The laboratory includes several pieces of equipment designed for destructive testing (tension, compression, bending, torsion) in a static regime, through which the mechanical and elastic characteristics of various tested materials can be determined. Among these, we mention:

The laboratory is equipped with the INSTRON 5587 automatic material testing machine for tension, compression, and buckling tests, which allows for the determination of the mechanical properties of materials. The machine has a static capacity of 300 kN and allows for automatic recognition and calibration of force, displacement, and deformation transducers.

Additionally, the laboratory includes the INSTRON 4303 automatic material testing machine, with a static capacity of 25 kN. The laboratory also contains various specific equipment for the plastic deformation processing of materials.

Some of the most advanced equipment used in the center are the GOM ARAMIS and ARGUS optical systems for measuring in-plane deformations and thickness reduction in deformed sheet metal parts. These systems allow the measurement of primary, secondary, and equivalent deformations on sheet metal parts following a cold plastic deformation operation. Additionally, it is possible to plot forming limit curves and material thinning during the deformation process. The deformation measurement systems include software packages for data evaluation and processing, with control for image recording and post-processing, automatic scanning of a series of images, and 2D and 3D visualizations.

The laboratory is also equipped with the latest model of the specific deformation and material thinning measurement system, the GOM ARAMIS 12M, which has a camera resolution of 12 megapixels. The image acquisition frequency can be up to 5Hz at maximum resolution and 150Hz at minimum resolution. The system is mainly used in tests performed on testing machines but also for other static load applications, such as sheet metal plastic deformation processes. The system also includes an enlarged column stand and a graphics workstation used for processing the acquired images.

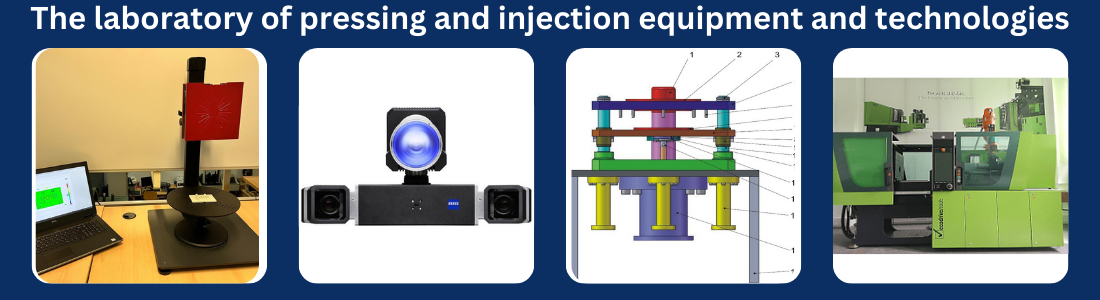

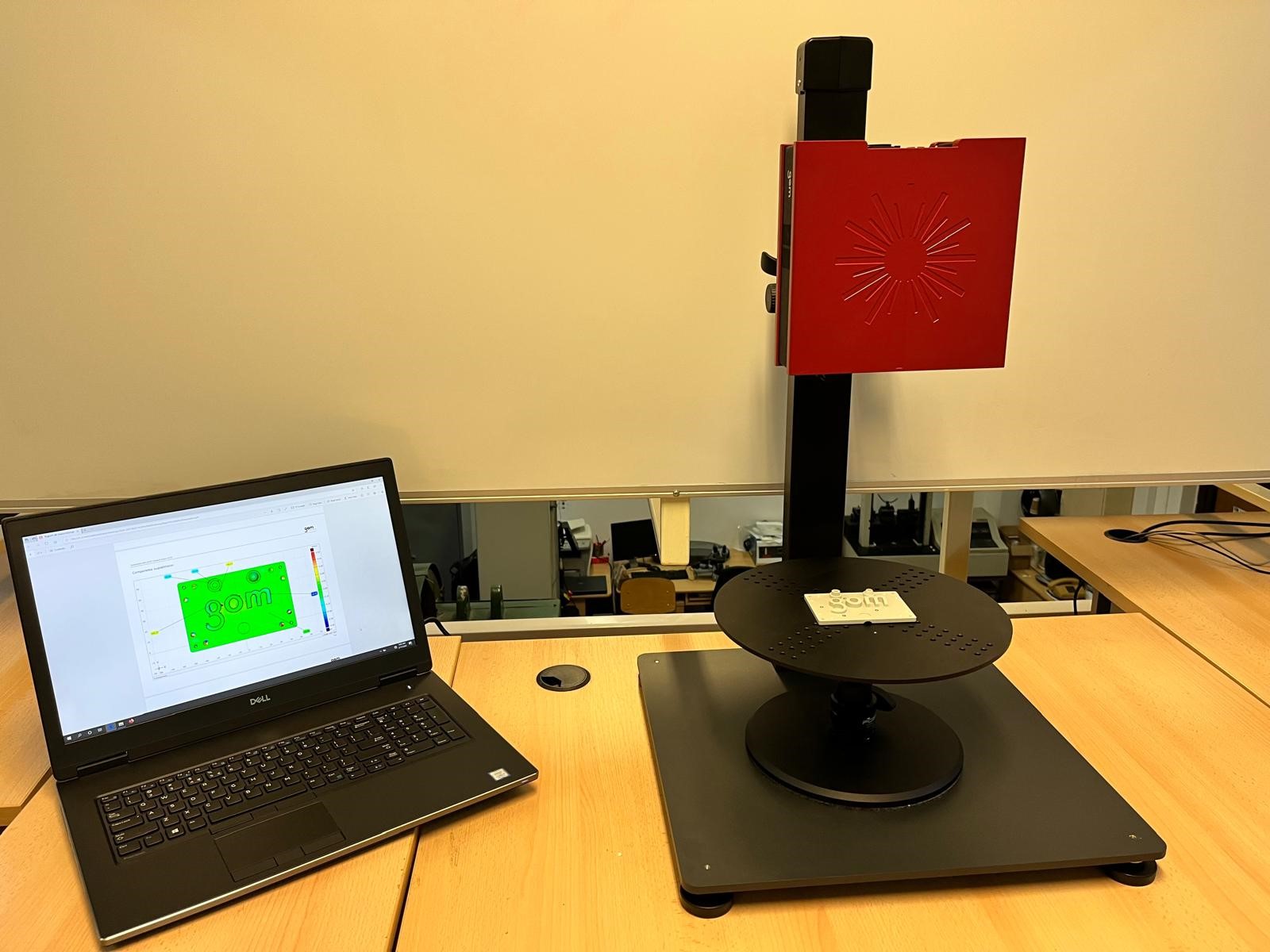

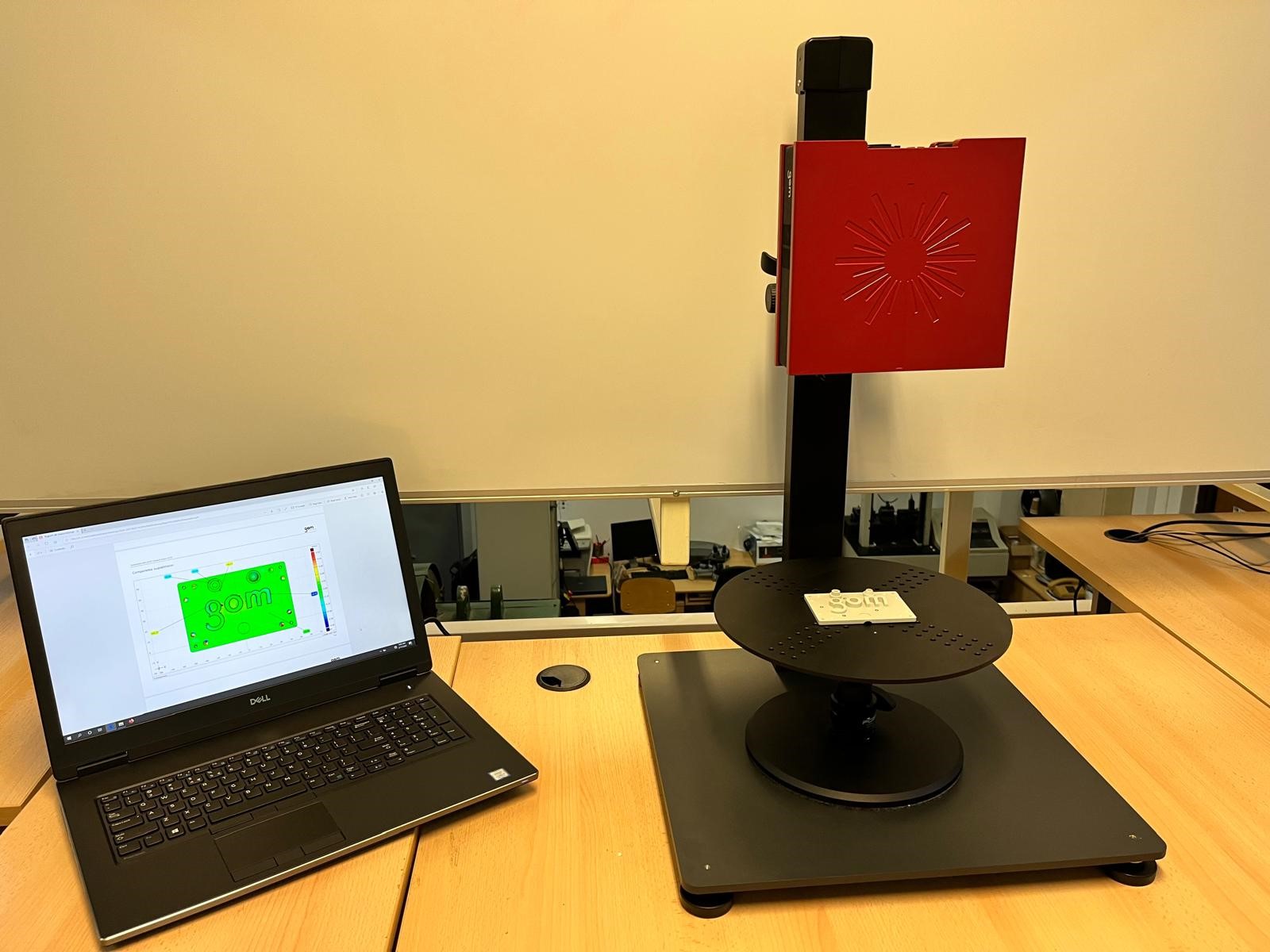

The Laboratory of Pressing Equipment and Technologies is equipped with the GOM ATOS CORE 200 3D optical measurement system. This system allows the measurement of a maximum area of 200 x 200 mm through two cameras positioned at the edges of the system, enabling the analysis of the geometry of parts using the triangulation method. The system facilitates the measurement and analysis of parts after plastic deformation processes. The system also includes a rotary stand for positioning, fixing, and clamping the parts, as well as the dedicated GOM INSPECT software package for data analysis and interpretation.

The laboratory features the Mitutoyo Surftest SJ-411 roughness tester, used for analyzing the surface roughness of parts. It allows for roughness measurements according to various standards such as EN ISO, VDA, ANSI, and JIS. The roughness tester can measure a horizontal distance of up to 25 mm, with a vertical range of ±400 µm. The horizontal linearity over the entire stroke is 0.3 µm. The stylus has a tip angle of 60° with a radius of 2 µm. It is accompanied by a column stand for fixation and a software package that facilitates saving measurements and generating reports.

The laboratory has functionally and constructively designed a device that enables Nakajima and Marciniak tests, as well as the determination of the Forming Limit Curve (FLC). The deep drawing device features a fixed active plate with the punch being actuated from the bottom. It consists of a modular deep drawing die, fixed on the device table (in the lower part), and hydraulic cylinders for actuating both the punch and the blank holder. The active elements of the die are: the punch, the active plate, and the blank holder; these elements are modular and quickly interchangeable, allowing for various types of deep drawing operations such as cylindrical, conical, and prismatic parts.

Among the injection molding equipment in the laboratory is the ARBURG 170-90-200 plastic injection molding machine, which has a clamping force of 250 kN, a maximum injection force of 91 kN, a maximum part volume of 20 cubic centimeters, and a maximum injection pressure of 3020 bar.

Also part of the injection molding machines group is the ENGEL VC 210/50 265302 series plastic injection molding machine, the 2024 model, which is a state-of-the-art machine provided on a custodial basis by ENGEL INJECȚIE S.R.L. Romania. ENGEL continuously updates the laboratory with the latest model of machines and peripheral equipment to ensure constant access to new technologies in the field of plastic injection molding. In addition to the machine itself, the laboratory is equipped with auxiliary devices for the plastic injection molding processes: a Koch type 608 vacuum loader, a KE-P4 color dosing unit, and an ONI LKKA 14 chiller.

The injection molding machine is equipped with a series of intelligent learning and connectivity devices such as IQ Clamp Control, IQ Flow Control, IQ Weight Control, as well as auxiliary connectivity devices (EDGE Device) specific to the "Industry 4.0" context. Additionally, ENGEL RO has equipped the laboratory with 50 educational software licenses for CADMould, version 17.0.1.4, a program dedicated to simulating the injection molding process.

The laboratory is equipped with additive manufacturing equipment, featuring a variety of 3D printers, each offering unique capabilities for different types of projects. Ultimaker 3 and Ultimaker 3 Extended: These FDM (Fused Deposition Modeling) printers are known for their precision and reliability, ideal for functional prototypes and end-use parts, with build volumes of 215 x 215 x 200 mm and 215 x 215 x 300 mm, respectively. Creality Ender 5 Pro: An affordable yet robust FDM printer, perfect for experimenting with different filaments and printing parameters, with a build space of 220 x 220 x 300 mm. FormLabs 2: Utilizes SLA (Stereolithography) technology, ideal for creating detailed, complex prototypes and high-quality functional parts, with a build volume of 145 x 145 x 175 mm.

Markforged Mark Two: Specializes in FDM printing with composite materials, allowing for the creation of highly durable parts suitable for industrial applications and research in advanced materials, with a build space of 320 x 132 x 154 mm. CraftBot Flow Idex and two CraftBot Plus Pro: Offer versatility through Independent Dual Extrusion (IDEX), facilitating printing with two different materials simultaneously and creating soluble support structures, with build spaces of 425 x 250 x 250 mm and 250 x 200 x 200 mm, respectively. The laboratory also benefits from a wide range of filaments and resins, including standard materials such as PLA and ABS, as well as technical materials like Nylon, carbon/glass fiber-reinforced polymers, PETG, TPU, and various photo-polymeric resins. This material diversity expands research possibilities, allowing detailed studies in areas such as optimizing printing processes, developing new composites, and analyzing the mechanical and thermal properties of printed parts. The Mayku FormBox thermoforming station further enhances the laboratory's capabilities, enabling the rapid creation of molds and thermoformed parts, useful for rapid prototyping and small-batch production. These advanced facilities allow for complex and innovative research, supporting the development and testing of new solutions in the field of additive manufacturing.

The Laboratory of Pressing and Injection also has a thermal imaging camera that allows temperature measurement with 4 spots, 4 areas, 3 isotherms DeltaT, and real-time thermal analysis.

The laboratory's equipment and technologies for pressing, cutting, and injection are complemented by CAD software packages (Catia v5 and SolidWorks) and CAE software packages (ABAQUS, ANSYS, DynaForm, AutoForm). Additionally, the laboratory features a high-performance data acquisition system consisting of the Keithley KPCI 3108 data acquisition board and the TestPoint software package.