iPP4CPPS

Cyber physical prototype representing a custom made small scale production system emphasizing Industry 4.0 concepts.

A production system prototype was developed in the Integrated product-production co-simulation for cyber-physical production system (iPP4CPPS) project to evaluate the maturity level of the INTO-CPS tool-chain coupled with 4DIAC for future adoption into a real manufacturing infrastructure by:

–Designing and building an integrated co-simulation;

–Delivering a proof-of- concept for deployment capabilities of INTO-CPS coupled with 20Sim and 4DIAC for the control of production system.

Festo MPS

MPS® 500-FMS provides the perfect platform for mastering industrial automation applications

Considering the fact that it is becoming more and more common for specialists and engineers to be responsible for operation and maintenance of complex automated production systems. This requires the seamless interaction of all the technologies involved.

MPS® 500-FMS forms the basis for general technological training using practical problems from actual operational applications.

Training system

Built on a modular hardware and software architecture, the training station is an adaptive system as an experimental practice playground for learning how to correctly assemble customizable products.

The entire set of devices, gadgets, sensors and applications available around the physical station favours a complete training process involving manual operations, starting from traditional digital experience, immersive scenarios collaborative exercises, supervised and assisted tasks, all the way to process analytics and AI guided suggestions for real-life assembly scenarios.

The software architecture revolves around a set of decentralized and specialized micro-services. Each application follows a specific training scope and uses the available services in a unique manner to reflect as much as possible a real industrial environment.

The station enables multi-modal interaction like verbal communication, tactile feedback, 3D gestures etc.

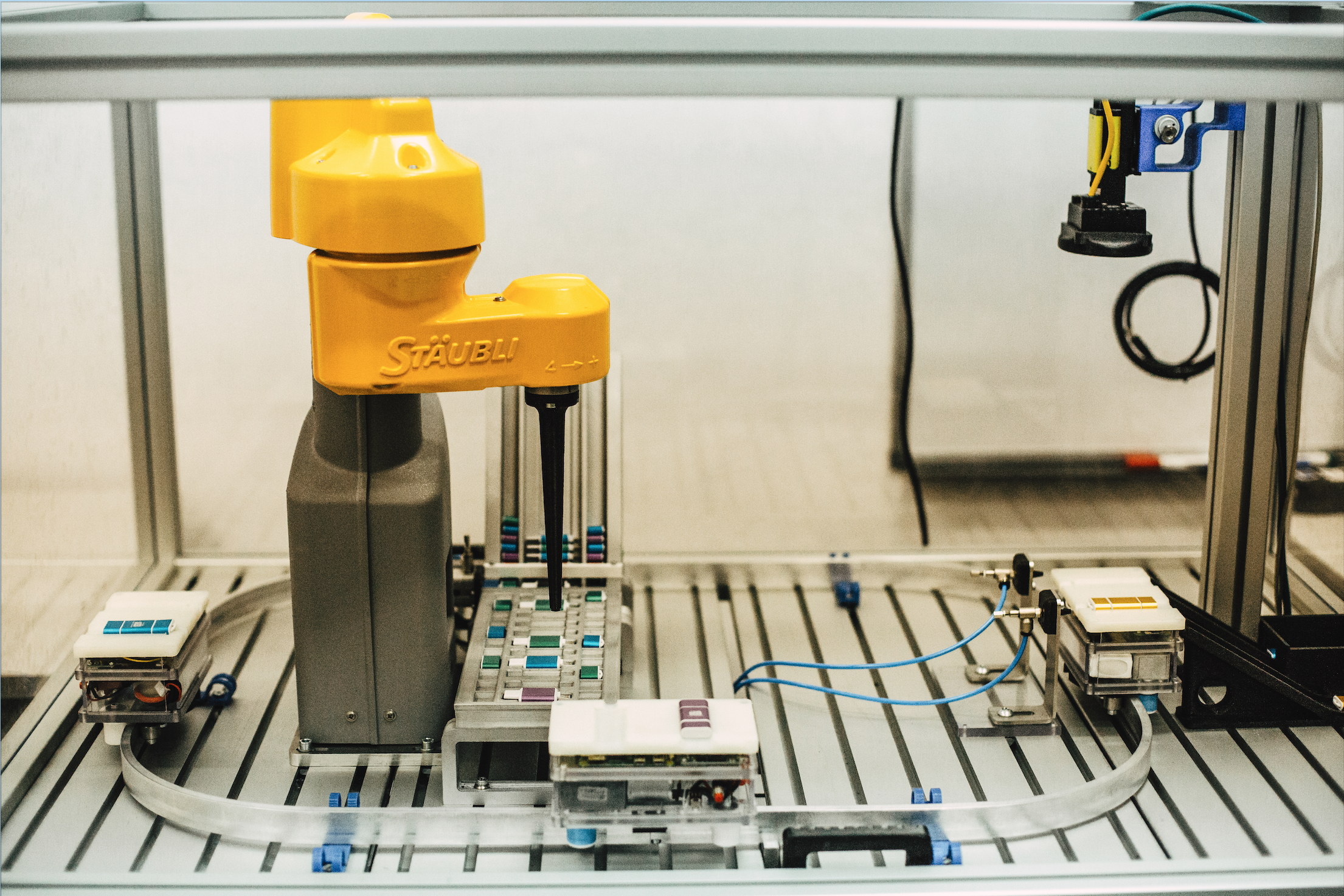

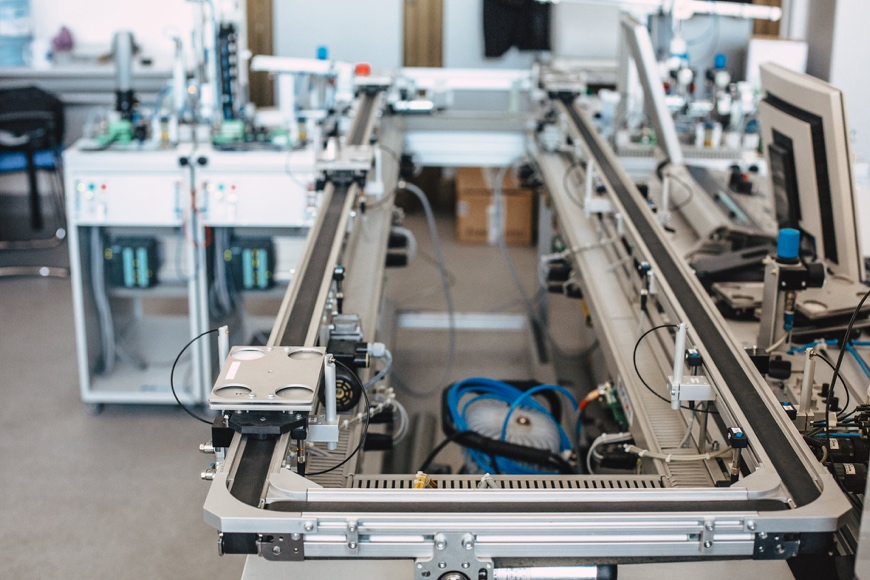

Production system

The automatic production prototype system is a small-scale but having similar complexity with real industrial production systems. The prototype has eight modules designed in accordance to Industry 4.0 principles enabling: interconnection, information transparency, technical assistance and decentralized decisions.

The production prototype can autonomously manufacture a standard smart product (i.e. functionally and chromatically customizable tablet) specially developed for this demonstrator or, assisted by a human operator it can produce customized versions of the same product in case of special orders. The material flow is enabled by autonomously guided vehicles which are permanently “negotiating” assignment of tasks with the higher planning system to pick-up, store or deliver to different modules (e.g. collaborative robot aided warehouse, CNC milling, automated assembly).

By its design, the prototype covers a large spectrum of manufacturing industries scenarios and enables testing of technologies in a realistic environment.

Copyrights © 2020 All Rights Reserved. Powered by INCON.