Courses

Location: Digital Transformation Lab, Engineering Faculty IM311

- 1. The role and function of Linux OS, Linux distributions

- 2. Some minimal OS specific commands

- Application of Linux commands and utilities. Equivalent Windows commands

- Working with the Linux Shell

- Managing Linux Files and Directories: create, delete, move, search files and find in files

- Text editors: vi, gedit, emacs.

- Learn how to install an application, how to download a library

- 3. Developing C/C++ programs on Linux

- Analysis of problem solving, compilation, assembling, link editing, troubleshooting (debugging) and execution of C / C ++ program.

- Command line compiling; writing makefile

- Using MonoDevelop for GUI applications

- Some differences between Linux and Windows regarding data representation, line endings characters, memory allocation for basic data types

- 4. Research environment for advanced computing architectures

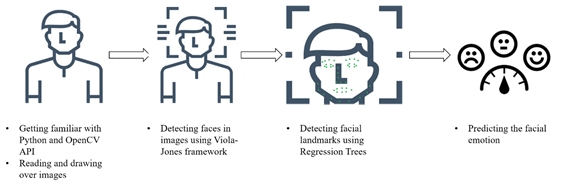

We offer a training module for learning to design, software implement and evaluate a new system for facial expressions / emotions recognition (FER) using different machine learning techniques that would ultimately perform better in terms of computational speed and accuracy than existing methods.

Applicability on “workplace safety: determine employees’ emotion recognition”; monitor a machine operator and detect the operator’s emotional state to avoid accident; determine drivers fatigue in the case of car driving. Send an alert if the operator is tired, distracted or angry. Also, such an application could verify that a construction, civil engineering, industry worker is equipped accordingly with protection gear. Or, if a worker that supervises an assembly line or maneuvers an excavator doesn’t feel well (looks distressed/ angry/sick), it could create multiple damages if not stopped or assisted before or during the task he is performing

The trainees will learn basics about Python and OpenCV programming, algorithms specific to Machine Learning from the SciKit learn library https://scikit-learn.org/stable/.

The participants can be people interested in Industry 4.0 technologies for creative engineering. The duration of the training is of 8 hours.

We offer a training module entitled "Smart city modelling" that has as principal objectives understanding and applying some modeling tools and methods for the design of specific smart city processes like smart traffic, smart parking, smart mobility, smart environment, in order to increasing the human wellbeing and decreasing the city crowding. The trainees will learn basics about:

- Understand and installing a modeling tool; Modeling tools presentation and theory about models; limitations and application area

- Modeling in ADOxx environment and optimizing smart cities specific processes: implement a model; methods for design of smart city modeling

- Web development applications for booking a place in the parking spot

- Communications between Web app with Raspberry Pi and IoT components commanding a line follower robots

- Develop an Open CV application for car counting

The participants can be people interested in Industry 4.0 technologies for creative engineering, municipality, decision factors, agencies. The training duration is of 12 hours.

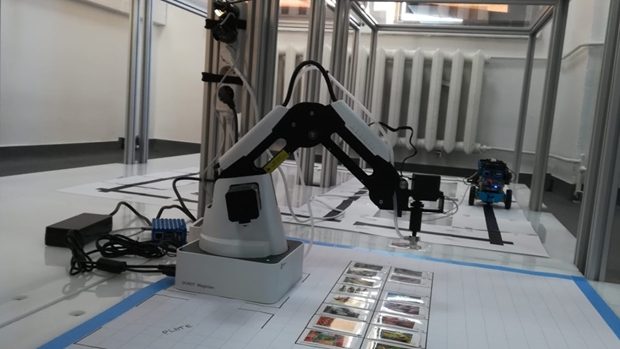

We offer a training module entitled "Introduction to Flexible Manufacturing System and Petri net". It aims modeling and simulation-based design and optimization of manufacturing systems and processes. The training includes also testing the models in the laboratory using a robotic arm. Robot manipulation and robot connectivity are available. The robot arm is used for executing the developed applications with Flowcharts or Petri Nets on the Bee-up and ADOxx platforms. The main modules of the training aim:

- Understand and apply a method for designing robust and deadlock free control solution for manufacturing systems

- Acquire operational skills on the use of Petri Nets tools for automation

- Stage 1: The trainees learn to model the plants and the automation system using the Petri net using a mix of think-pair-share and problem solving

- Stage 2: The trainees learn to express the automated system specification as Petri Net properties that must be satisfied using a mix of case studies and problem solving

- Stage 3: The trainees solve problems of a manufacturing system automation

The participants can be people interested in smart manufacturing, Industry 4.0 technologies for creative engineering. The training duration is of 16 hours.